Gaskets

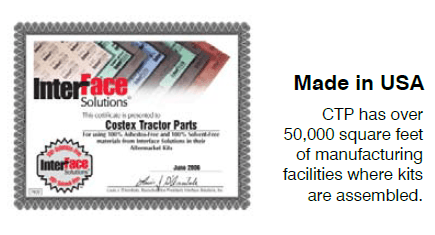

At CTP we design and manufacture gaskets from

materials that are engineered to withstand the high

pressures and temperatures of today’s diesel engines.

As an engine gasket supplier we are an Interface

Solutions Inc. Certified Partner. Our Gaskets provide

component integration, resulting in durability and

reliability, with the quality and value CTP customers

have come to expect.

CTP GASKET MATERIALS & SPECIFICATIONS

Gaskets are produced from 100% solvent free, environmentally friendlly, asbestos free materials. All materials are treated with an anti-stick coating on both sides to better protect the gasket and the machine itself.

| Material | Gasket Type | Material | Application | Maximum Short Duration Temperatures | ||

|---|---|---|---|---|---|---|

NCA-45  |

Cork Gasket | Cork/synthetic rubber blend | Medium Oil resistance of most Sealing application: • Valve Covers • Oil Pans • Transmission Pans |

up to 200°C (392°F) | ||

CMP-4000  |

Paper Gasket | Compressed MicroPore material, combining a unique synthetic fiber matrix and fully cured Nitrile Butadiene rubber binder | Excellent seability and torque retention properties for OEM and Industrial Applications. | up to 350°C (650°F) | ||

HFL-171  |

Paper Gasket | Fully cured Nitrile Butadiene rubber binder | Heavy-duty and Industrial Applications: • Diesel engine • Transmission • Refrigeration • Piping |

up to 290°C (550°F) | ||

HFL-781  |

Paper Gasket | Controlled swell gasket material with Styrene Butadiene and natural rubber binders | Heavy-duty oil sealing Applications: Diesel engine Oil pans Front covers |

up to 290°C (550°F) | ||

M5201  |

Paper Gasket | High-density material with fully cured Nitrile Butadiene rubber binder | Heavy-duty Diesel engine Applications: • Oil resistance • Fuel resistance |

up to 290°C (550°F) | ||

MP-15  |

Paper Gasket | MicroPore with a Nitrile Butadi- ene binder | Excellent low flange pressure seability and bolt torque reten- tion for heavy-duty applications: • Compressors • Diesel engines • Others |

up to 205°C (400°F) | ||

N-8092  |

Paper Gasket | Reinforced Cellulose with Nitrile binder | Excellent crush resistance at high flange pressure for small Engine and Compressor Applications: • Oil • Fuel • Water |

up to 180°C (350°F) | ||

| Material | Gasket Type | Material | Application | Maximum Short Duration Temperatures | ||

|---|---|---|---|---|---|---|

PF-4S  |

Paper | Gasket | Synthetic fibers, advanced fill- ers and Nitrile Butadiene bind- ers | Various Oil, Air, and Coolant Applications: • Oil pans • Front covers • Intake manifolds • Rear seals |

up to 290°C (550°F) | |

RN8011  |

Paper | Gasket | Low density Cellulose fiber ma- terial with high rubber filler content and Nitrile Butadiene rubber binder | Excellent sealing at low flange pressures for Oil and Water Applications: • Engine • Transmission pan gaskets • Water pumps • Environmental seals |

up to 180°C (350°F) | |

S-8091  |

Paper | Gasket | Latent cure Styrene Butadiene bound material with reinforced Cellulose fiber | Excellent sealing for: • Oil • Fuel • Low-pressure Steam |

up to 180°C (350°F) | |

TS-9016  |

Paper | Gasket | Fully cured Styrene Butadiene rubber binder and a blend of Ar- amid and Cellulose fibers | Oil and Water Applications | up to 290°C (550°F) | |

VB-72  |

Paper | Gasket | MicroPore with a Nitrile Butadi- ene binder | Heavy-duty applications: • Valve body • Applications with high fluid pressures and flow rates exposure • Erosion Resistance |

up to 290°C (550°F) | |

EMC-7201  |

Metal | Gasket | Composite structure of high- density, fully cured Nitrile Butadiene bound gasket facings chemically and mechanically fused to an expanded steel core | High performance Diesel engine structural joint applications: • Gear case • Flywheel housings • High pressure hydraulic joints |

||

HTX-900 7%  |

Metal | Gasket | Graphite-coated, high tempera- ture facing material chemically and mechanically fused to an expanded steel core | High strenght, thermal integrity, and anti-stick performance sealing applications: • Exhaust manifolds • Header • Collector • EGR system gaskets |

||

ML6  |

Metal | Gasket | Non-asbestos Cellulose fiber combined with Nitrile latex and thermosetting resins | High Performance, non-extruding metal support sealing application: • Intake manifolds • Transmission • Braking system • Industrial Applications |

up to 205°C (400°F) | |

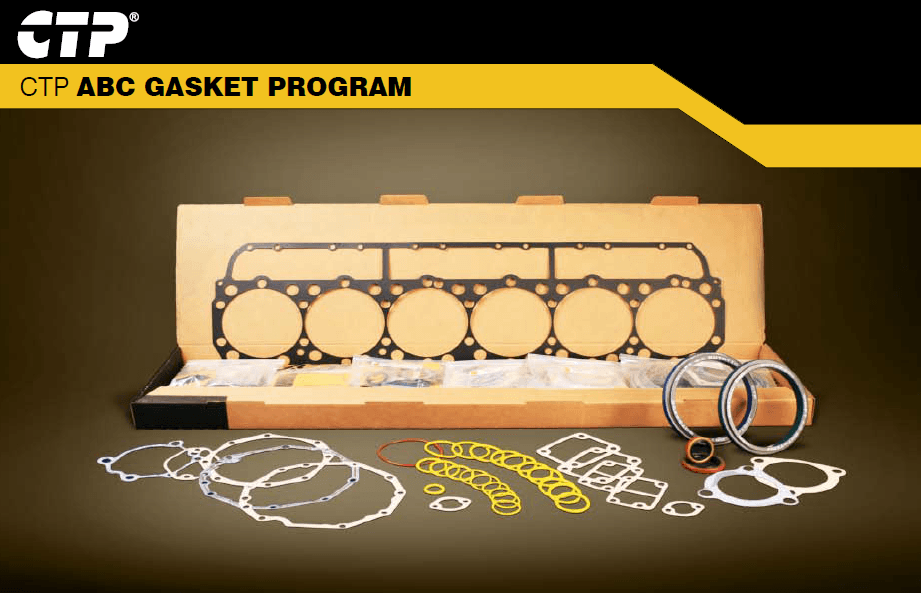

ABC Gaskets Kits

The ABC Gasket Kit Program is designed to consolidate gasket kits and make it easier for the parts person to order and for the rebuilders himself to quickly identify and organize their seals and gaskets. At the same time, they can be

assured that everything they need is included for each particular rebuild.

Kits are packed into sub kits (Front set, rear set, lower set, etc.) inside the gasket kit for easy identification.

The ABC Gasket Kit Program offers you the

following:

1. Find everything in 1 box instead of 10 boxes.

2. Kits are divided and labeled into sub-kits inside the

gasket kit box for easy identification.

3. Less shipping cost. (1 box instead of 10 boxes).

4. Less warehouse space (1 box compared to 10

boxes).

5. Faster inventory turnover.

6. More machine coverage with lower investment in in

ventory. (Each special kit covers a wide range of

serial numbers)

7. Simplified part numbers are included in a kit for a

particular rebuilt (inframe, out of frame or a head set)

You won’t have to worry that anything is missing.

How to choose from the different sets of kits:

A = Out of Frame Overhaul Set

B = Inframe Overhaul Set

C = Multiple Cylinder Head Replacement Set

Other options are identified with the letters D or E.

The part numbers are designated as follows:

CTP + engine number + Consecutive Number + ABC

(D or E suffix if available).