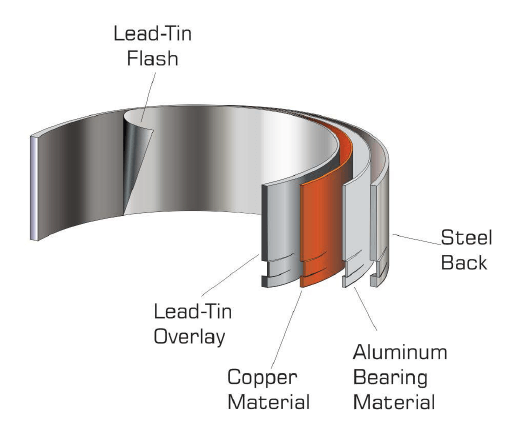

CTP copper bonded bearings are more resistant to scuffing than nickel bonded bearings. Because copper reduces contact friction by 50% over nickel, copper bonding agent is superior to nickel type bonding agents used in other bearings. These bearing composites are engineered for durability, conformability and embedded ability, while providing high strength and high wear resistance. Field experience has proven that copper bonded bearings in engines with correct maintenance do not normally require replacement. Copper bonded bearings will

reduce downtime and operating cost.

Features:

– Improved fatigue strength due to the strong intermediate layer and hardening effect of copper in the relatively thin overlay.

– Excellent seizure resistance provided by the lead based overlay. Seizure resistance drops sharply when the overlay is removed in direct metal-to-metal contact.

– Excellent conformability for small misalignments.

| Part No. | Engine Model |

|---|---|

| 3285572 | 3304, 3306 |

| 3285573 | 3406/C/E |

| 3285574 | 3412 |