Selecting the right gasket material is vital for gasket performance. Gaskets and seals primary functions are to compress and seal under high demand; compensating for mating surface irregularities at high temperatures and stresses. As a guard against gas or fluid flow, gaskets have to function at a level that meets the needs of heavy machinery as well have a wide variety of types to choose from.

CTP offers a large selection of N-8092 Gasket Material from Interface Solutions™ that fits a plethora of applications, and our sales experts are always happy to help on choosing the right material for gaskets from your first question to your last.

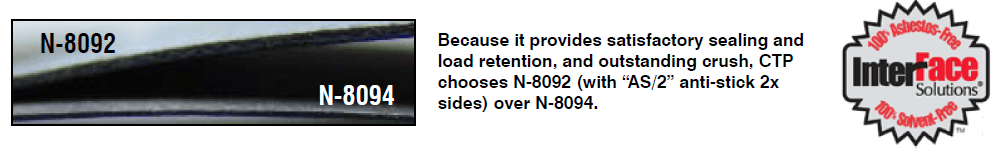

Why does CTP choose N-8092?

- N-8092 is produced at a higher minimum density (40% more) than N-8094 (8092 = 1.20 g/cc or 75 lbs./cu.ft. min. versus 8094 = 0.87 g/cc or 54 lbs/cu.ft. min).

- N-8092 has a tighter pore structure that will resist permeation of fluids much better than N-8094.

- N-8092 seals oil at almost half the required load needed to seal N-8094 at the same gasket thickness and flange load.

- N-8092’s sealabilty performance in a pressurized gas environment is more than 2 x better than N-8094.

- N-8092 resists creep better than N-8094 to provide better bolt load retention over time. Higher joint tightness = longer- term sealing durability.

Gasket Material

All materials are treated with an anti-stick coating on both sides to better protect the gasket and the machine itself.

| Material | Texture | Gasket Type | Material | Application | Maximum Short Duration Temperatures |

|---|---|---|---|---|---|

| NCA-45 |  | Cork Gasket | Cork/ Synthetic Rubber Blend | Medium Oil Resistance of Most Sealing Application:

| up to 200°C (392°F) |

| CMP-4000 |  | Paper Gasket | Compressed MicroPore Material, combining a unique synthetic fiber matrix and fully cured Nitrile Butadiene rubber binder | Excellent seability and torque retention properties for OEM and Industrial Applications. | up to 350°C (650°F) |

| HFL-171 |  | Paper Gasket | Fully cured Nitrile Butadiene rubber binder | Heavy-Duty and Industrial Applications:

| up to 290°C (550°F) |

| HFL-781 |  | Paper Gasket | Controlled swell gasket material with Styrene Butadiene and natural rubber binders | Heavy-Duty Oil Sealing Applications:

| up to 290°C (550°F) |

| M5201 |  | Paper Gasket | High-Density material with fully cured Nitrile Butadiene rubber binder | Heavy-Duty Diesel Engine Applications:

| up to 290°C (550°F) |

| MP-15 |  | Paper Gasket | MicroPore with a Nitrile Butadiene binder | Excellent low flange pressure sealing and bolt torque retention for heavy-duty applications:

| up to 205°C (400°F) |

| N-8092 |  | Paper Gasket | Reinforced Cellulose with Nitrile Binder | Excellent crush resistance at high flange pressure for Diesel Engines and Compressor Applications:

| up to 180°C (350°F) |

| PF-4S |  | Paper Gasket | Synthetic Fibers, Advanced Fillers and Nitrile Butadiene Binders | Various Oil, Air, and Coolant Applications:

| up to 290°C (550°F) |

| RN8011 |  | Paper Gasket | Low density Cellulose Fiber Material with High Rubber Filler Content and Nitrile Butadiene Rubber Binder | Excellent sealing at Low Flange Pressures for Oil and Water Applications:

| up to 180°C (350°F) |

| S-8091 |  | Paper Gasket | Latent cure Styrene Butadiene bound material with reinforced Cellulose fiber | Excellent sealing for:

| up to 180°C (350°F) |

| TS-9016 |  | Paper Gasket | Fully Cured Styrene Butadiene rubber binder and a blend of Aramid and Cellulose fibers | Oil and Water Applications | up to 290°C (550°F) |

| VB-72 |  | Paper Gasket | MicroPore with a Nitrile Butadiene binder | Heavy-duty applications:

| up to 290°C (550°F) |

| EMC-7201 |  | Metal Gasket | Composite structure of High-Eensity, Fully Cured Nitrile Butadiene bound gasket facings chemically and mechanically fused to an expanded steel core | High performance Diesel engine structural joint applications:

| N/A |

| HTX-900 7% |  | Metal Gasket | Graphite-Coated, Jigh Temperature facing material chemically and mechanically fused to an expanded steel core | High Strength, Thermal Integrity, and Anti-Stick Performance Sealing Applications:

| N/A |

| ML6 |  | Metal Gasket | Non-Asbestos Cellulose Fiber combined with Nitrile Latex and Thermosetting Resins | High Performance, non-extruding metal support sealing applications:

| up to 205°C (400°F) |